Inquiry from WEB

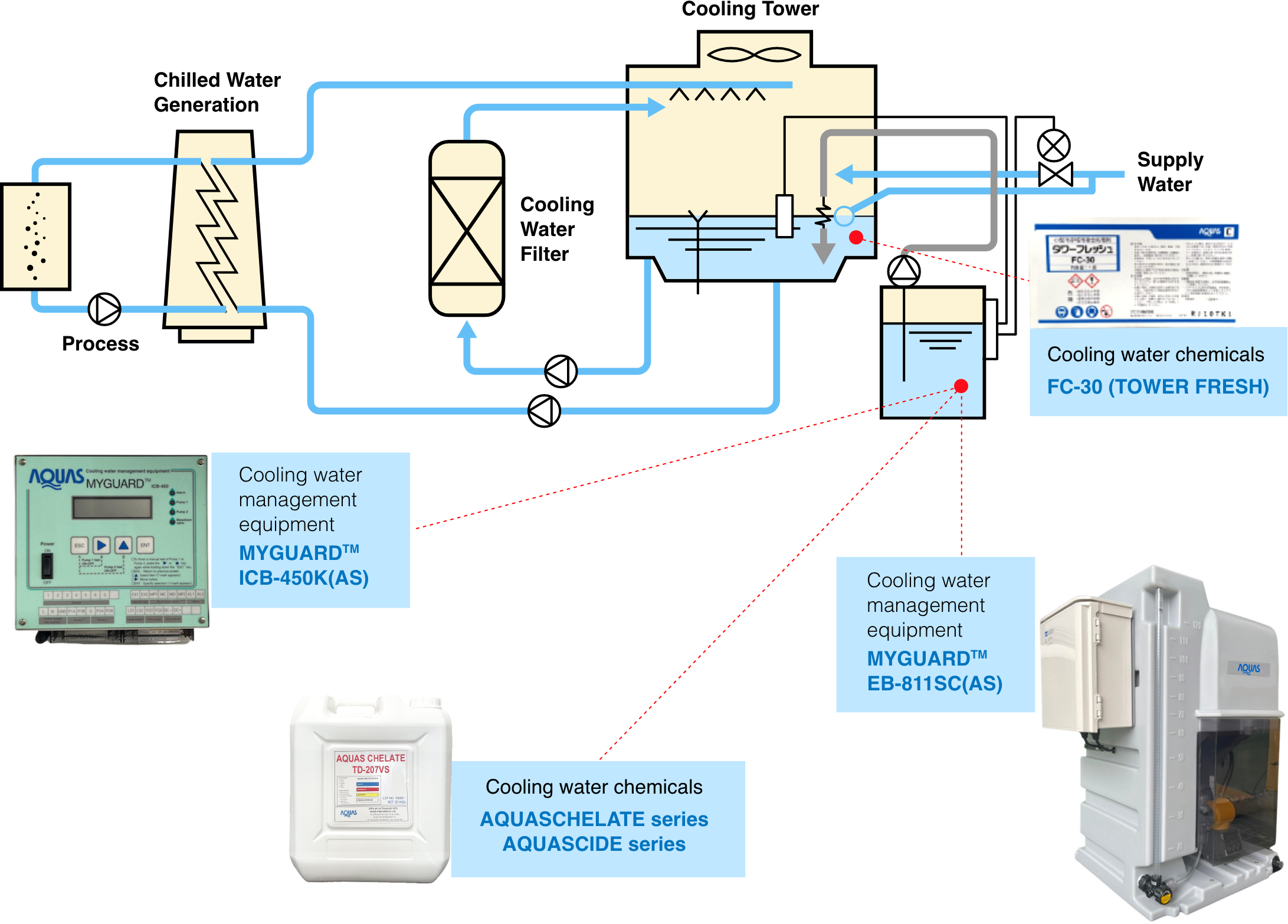

CONTACT FORMFor refrigeration equipment cooling water, open circulation systems with cooling towers are commonly used. In towers, the cooling (circulating) water is partly evaporated to exploit the latent heat of vaporization and thereby cool the water. This causes salts contained in the cooling water to be condensed, which is likely to cause various problems. At the surface of the heat exchanger the temperature of the cooling water rises, reducing the solubility of the salts and causing scale to easily accumulate on the surface of the heat exchanger.

- • Increased concentrations of salts dissolved: accumulation of scale and sludge on the heat exchanger

- • Increased corrosive materials: corrosion

- • Increased salts and organic materials: accumulation of slime, contamination due to Legionella

Those problems may reduce the efficiency of the heat exchanger, leading to increased energy consumption or refrigerator operation failure due to a primary cutout. Alternatively, corrosion may reduce the equipment life markedly, affecting the refrigerator operation.

Our water treatment prevents such problems to support normal refrigerator operation.

Problem with refrigerators and

preventive effects

-

Build-up of slime on

a cooling water system -

Adding water treatment

chemicals reduces growth

of algae. -

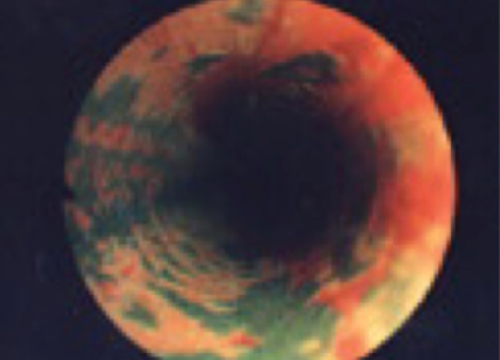

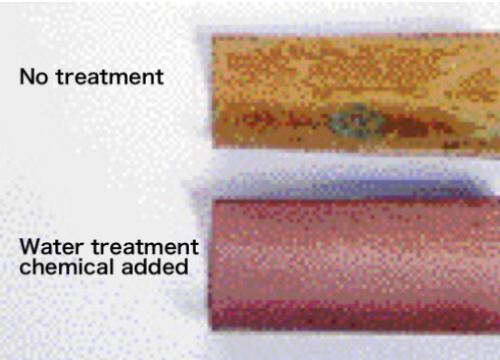

Corrosion on a copper

heat exchanger tube in

a refrigerator -

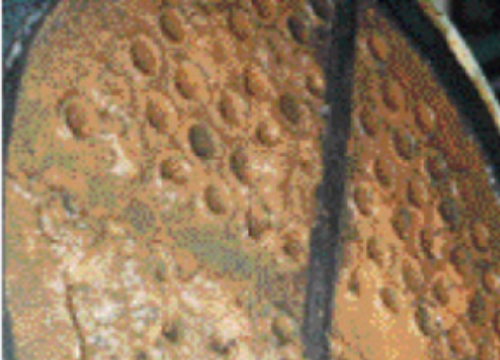

Build-up of scaling on

a heat exchanger in

a refrigerator -

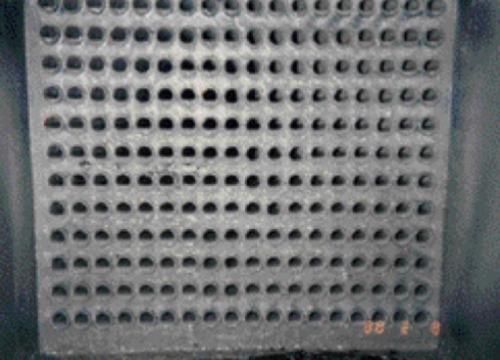

Effects of corrosion-

prevention on a copper

heat exchanger tube in

a refrigerator -

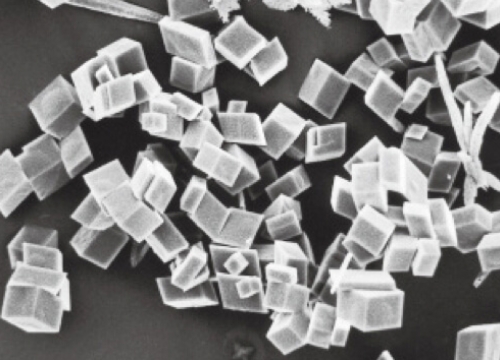

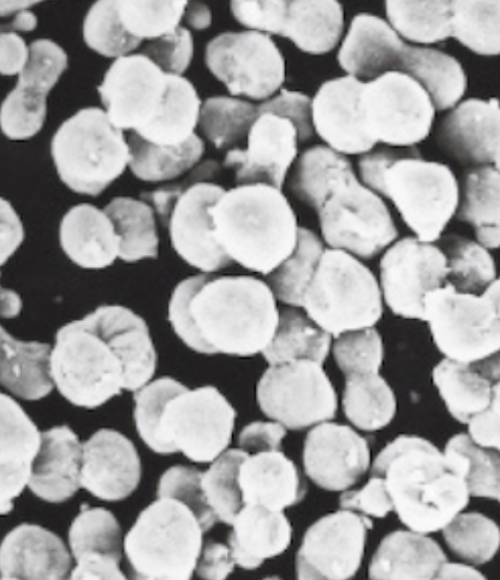

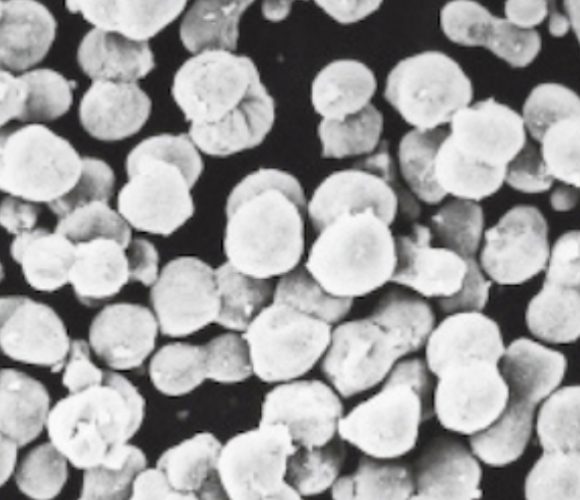

Calcium carbonate crystals

with no water treatment

chemicals added -

Calcium carbonate crystals with chemicals added to prevent scale Water treatment chemicals changed crystal form. The chemicals suppress the growth of crystals and prevent their accumulation as scale.

Chemicals

AQUAS™CHELATE TD series: Corrosion and scale inhibitor for cooling water

AQUAS™CHELATE TP series: Scale inhibitor for cooling water

AQUAS™CIDE TSC series: Biocides for cooling water

Equipment

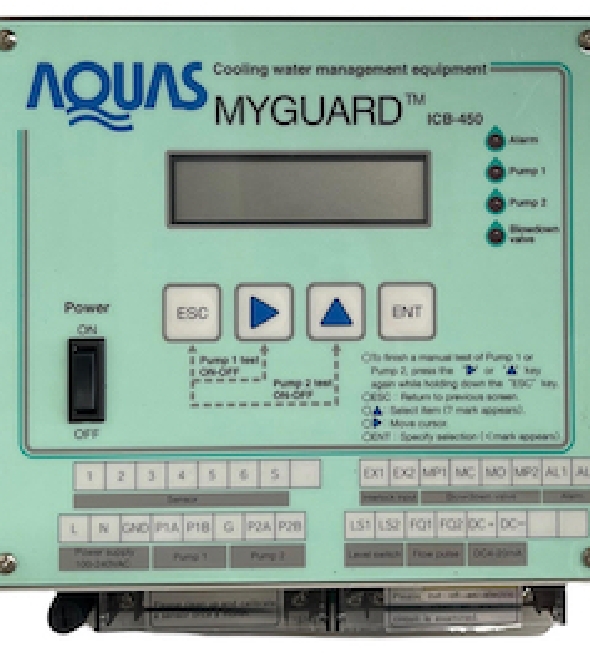

COOLING WATER MANAGEMENT EQUIPMENT

MYGUARD™ ICB-460K(AS)

MYGUARD™ ICB-460K(AS) is equipment designed to control the concentration of cooling water by controlling the blowdown valve according to the electric conductivity of the cooling water.

It also can control chemical feeding pumps, so it is possible to feed water treatment chemicals to cooling water appropriately using existing chemical feeding equipment.

COOLING WATER MANAGEMENT EQUIPMENT

MYGUARD™ EB-811SC(AS)

The MYGUARD™ EB-811SC(AS) is a cooling water management device for managing the electrical conductivity of cooling water and controlling chemical feeding with the EB-800(AS) system. The EB-800(AS) system, chemical feeding pumps and chemical tanks are integrated, enabling cooling water to be managed using only this system.

-

MYGUARD™ EB-811SC(AS)

-

EB-800(AS) system