Inquiry from WEB

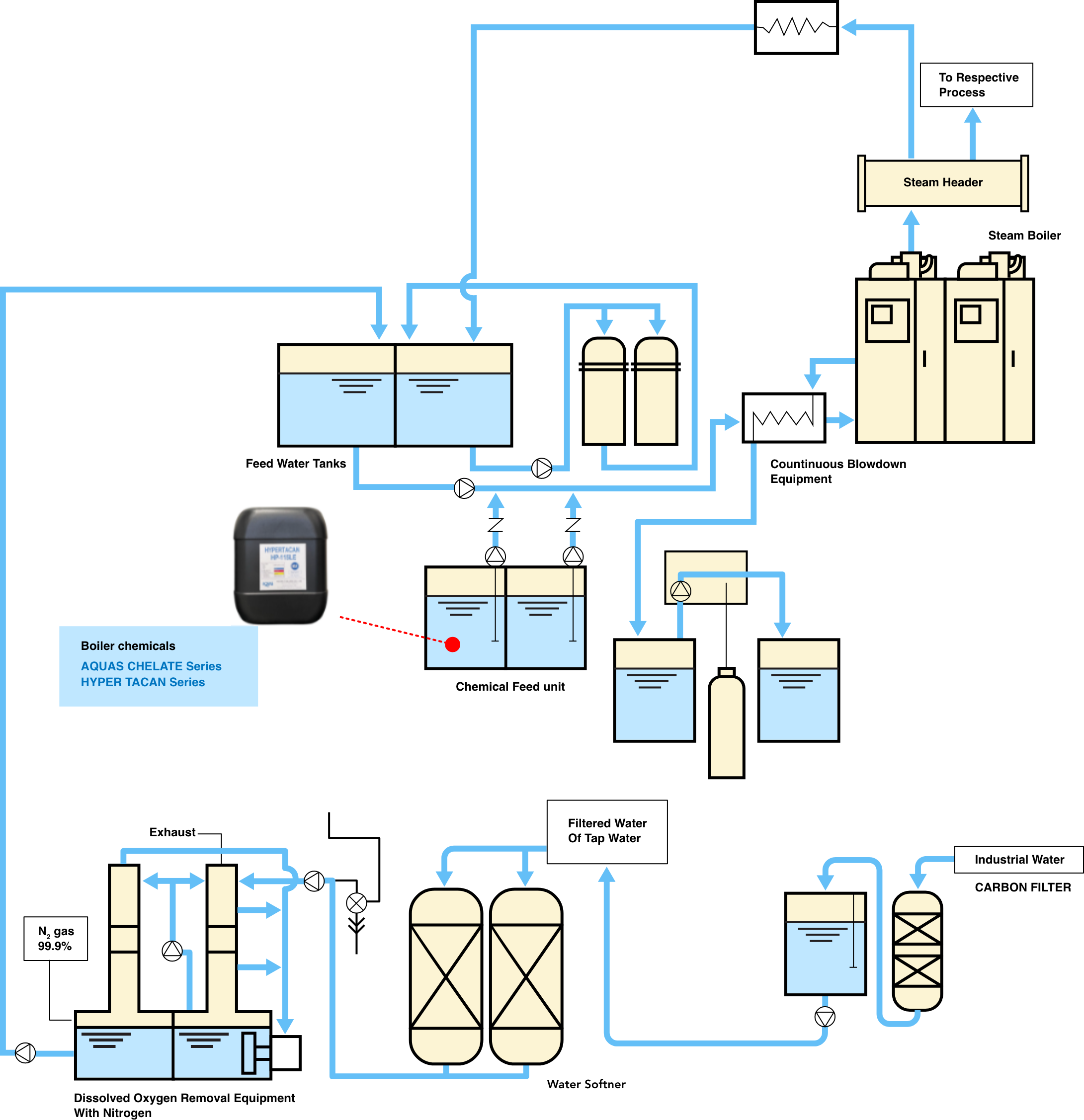

CONTACT FORMIf water is fed to boiler as it is, with no appropriate treatment, components contained in the boiler feed water can cause various problems.

- • Cations (calcium, magnesium, iron, sodium, etc.): scale, corrosion, carry-over

- • Anions (bicarbonate, chloride, sulfate, nitrate): corrosion

- • Non-ions (silica, free carbonic acid, resolved oxygen): scale, corrosion

In order to prevent such problems and operate your boilers efficiently and safely, it is essential to treat the feeding water with, for example, a water softener or a demineralizer, and to add boiler water treatment chemicals properly.

Boiler water treatments may vary widely depending on the conditions of the boiler plant, such as the boiler model, operating conditions, and supply water quality. We will suggest the water treatment most appropriate to your needs.

Problem in Boiler Plants

-

Corrosion on a flue and smoke tube boiler

-

Corrosion on a water tube

boiler -

Corrosion on a once-

through boiler -

Build-up of scale on a flue

and smoke tube boiler -

Inside a boiler operated

safely with water

treatment -

Corrosion on a condensed

water pipe -

Effects of using water

treatment chemicals for

corrosion prevention on

a condensed water pipe

CHEMICALS

AQUAS™CHELATE TD series: Scale inhibitor for boiler water

AQUAS™CHELATE TB series: Boiler chemical

AQUAS™CHELATE TMC series: Multi effect boiler chemicals

AQUAS™CHELATE TAW series: Antifoaming agent

SABINORU TH series: Oxygen scavenger

SABINORU TAFS series: Oxygen scavenger for food industry

SABINORU TDHS series: Oxygen scavenger

SABINORU TAL series: Oxygen scavenger for food industry

HYPERTACAN HP series: Scale inhibitor for food industry

POWER ATTACK TV series: Improve pH for boiler water